-

Injection Molding: A Comprehensive Overview

Injection molding is one of the most widely used manufacturing processes for producing high-volume plastic parts with intricate designs and precise specifications. It plays a crucial role in industries ranging from automotive to consumer electronics, providing a cost-effective and efficient means...Read more -

Comprehending ABS Shot Molding

Abdominal shot molding refers to the procedure of injecting molten abdominal plastic into a mold at high stress and temperature levels. There are lots of ABS injection molding applications as it is an extensively used plastic and can be found in the automobile, customer item, and building sectors...Read more -

What are Warm Resistant Plastics?

Plastics are utilized across practically every market because of their convenience of manufacture, inexpensive, and wide range of buildings. Over and above typical commodity plastics there exists a class of sophisticated heat immune plastics that can hold up against temperature levels that can no...Read more -

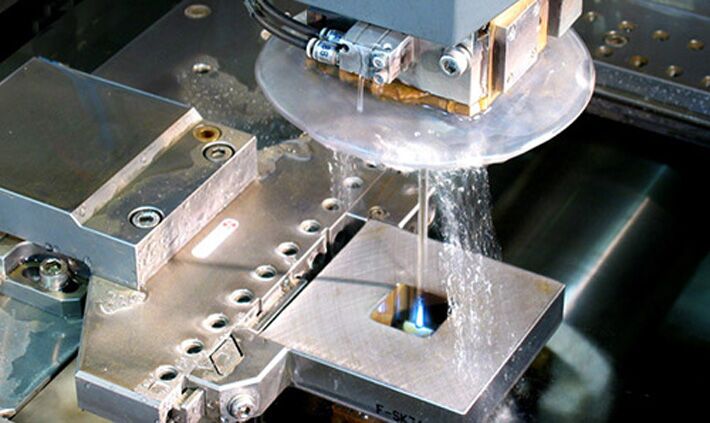

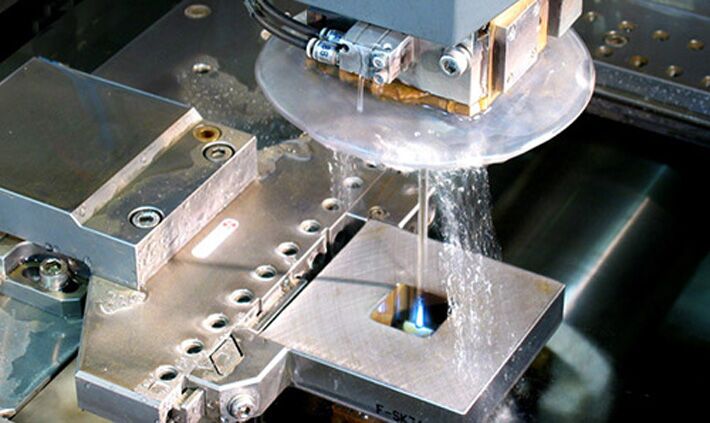

How does wire EDM work in mold making?

Electric discharge machining technology(EDM technology) has revolutionized manufacturing, especially in the field of mold making. Wire EDM is a special kind of electric discharge machining, which plays a vital role in the production of injection molds. So, how does wire EDM play a role in mold fo...Read more -

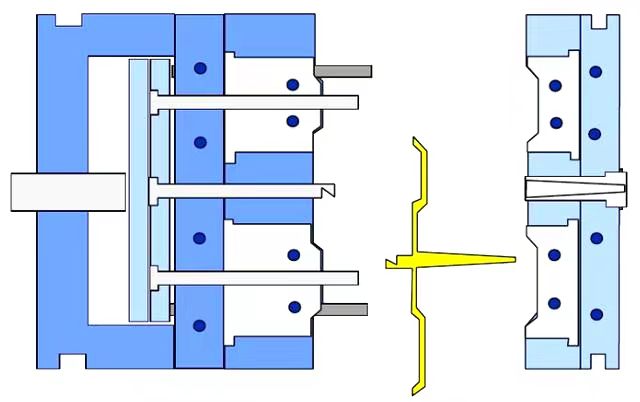

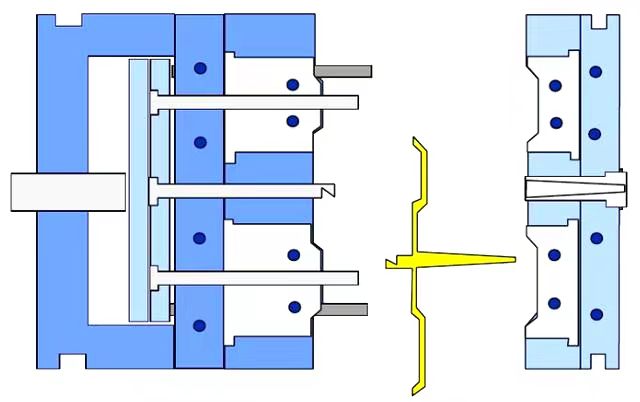

The difference between two plate mould and three plate mould

Injection molding is a widely used manufacturing process for producing plastic parts in large volumes. It involves the use of injection molds, which are essential tools for shaping and forming plastic materials into the desired shapes....Read more -

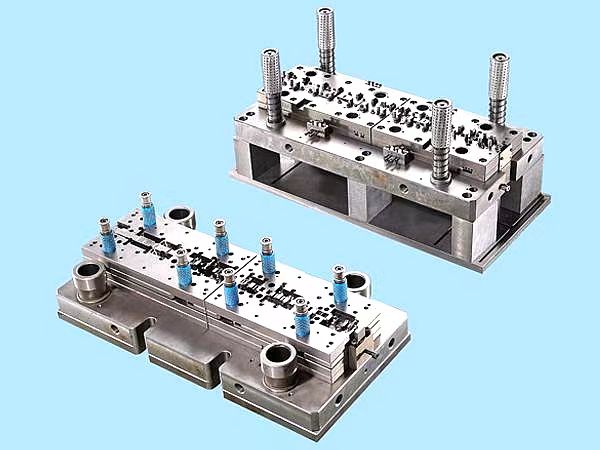

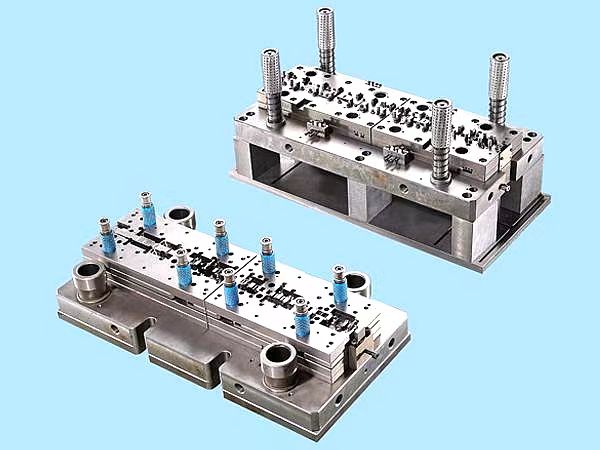

What is the stamping mould?

Stamping mould are essential tools in the manufacturing industry for creating precise and consistent shapes on sheet metal. These molds are typically manufactured in China, a leading producer of high-quality stamping molds known for their precision and durability. So, what exactly is a sta...Read more -

Why is CNC suitable for prototyping?

CNC (computer numerical control) machining has become a popular method for creating prototypes, especially in China, where manufacturing is booming. The combination of CNC technology and China’s manufacturing prowess makes it a top destination for companies looking to manufacture high-quality pro...Read more -

The role of EDM technology in injection molding

EDM(Electric Discharge Machining) technology has revolutionized the injection molding industry by providing precise and efficient solutions for the manufacture of complex molds. This advanced technology significantly improves the manufacturing process, making it possible to produce complex, high-...Read more -

Common defects in injection molding of small home appliances

Injection molding is a manufacturing process widely used in the production of small appliances. The process involves injecting molten material into a mold cavity where the material solidifies to form the desired product. However, like any manufacturing process, injection...Read more -

Comparison of the advantages and disadvantages of four common prototyping processes

1. SLA SLA is an industrial 3D printing or additive manufacturing process that uses a computer-controlled laser to manufacture parts in a pool of UV-curable photopolymer resin. The laser outlines and cures the cross-section of the part design on the surface of the liquid resin. The cured layer is...Read more -

Common surface treatment processes and their applications

1. Vacuum Plating Vacuum plating is a physical deposition phenomenon. It is injected with argon gas under vacuum and the argon gas hits the target material, which separates into molecules that are adsorbed by the conductive goods to form a uniform and smooth layer of imitation metal surface. Adva...Read more -

What are the applications of TPE materials?

TPE material is a composite elastomeric material modified with SEBS or SBS as the basic material. Its appearance is white, translucent or transparent round or cut granular particles with a density range of 0.88 to 1.5 g/cm3. It has excellent ageing resistance, wear resistance and low temperature ...Read more

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur