-

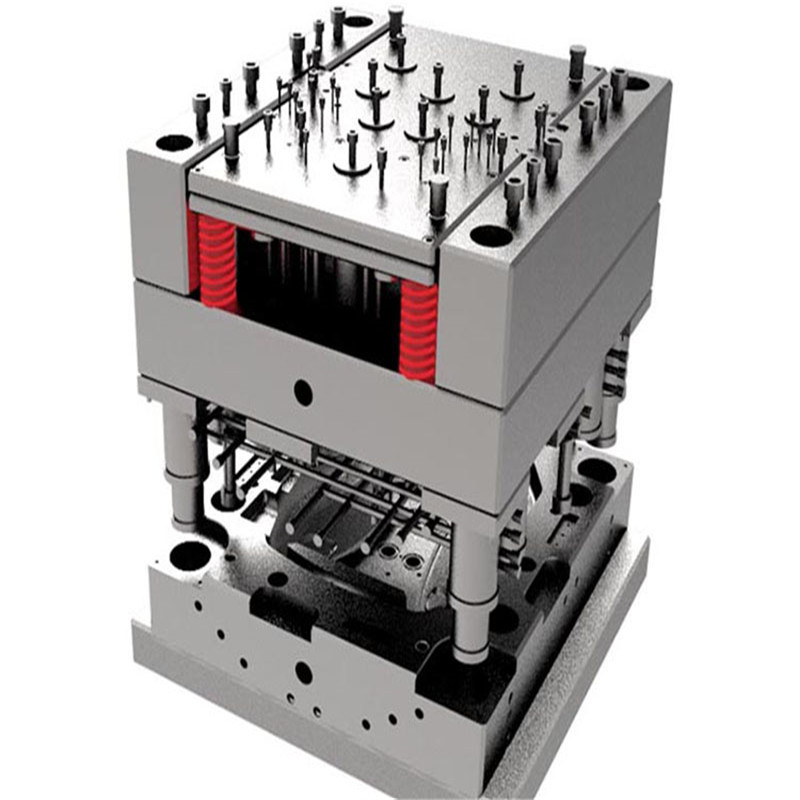

What factors can affect the life of a mould?

Any object has a certain service life, and injection moulds are no exception. The life of an injection mould is one of the important indicators to evaluate the quality of a set of injection moulds, which are affected by a variety of factors, and only with a complete understanding of them can we p...Read more -

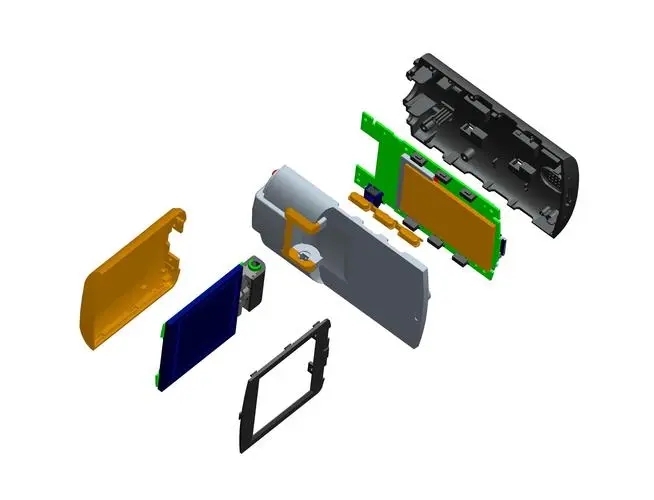

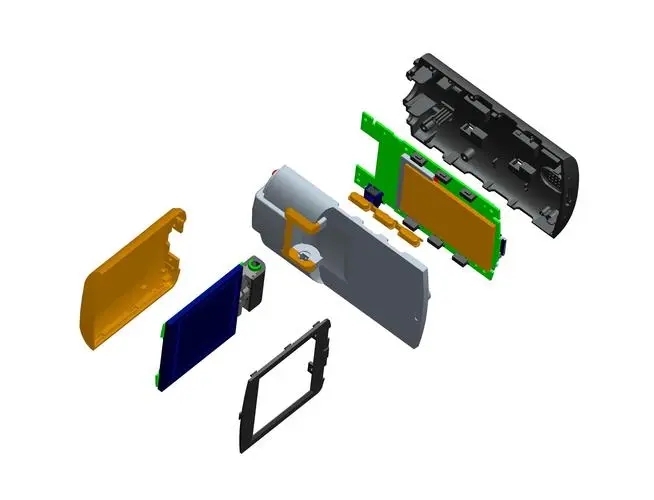

What are the common injection molding processes used in the production of small home appliance shell injection parts?

Plastic is a synthetic or natural polymer, compared to metal, stone, wood, plastic products have the advantages of low cost, plasticity, etc. Plastic products are widely used in our lives, the plastics industry also occupies an extremely important position in the world today. In recent years, som...Read more -

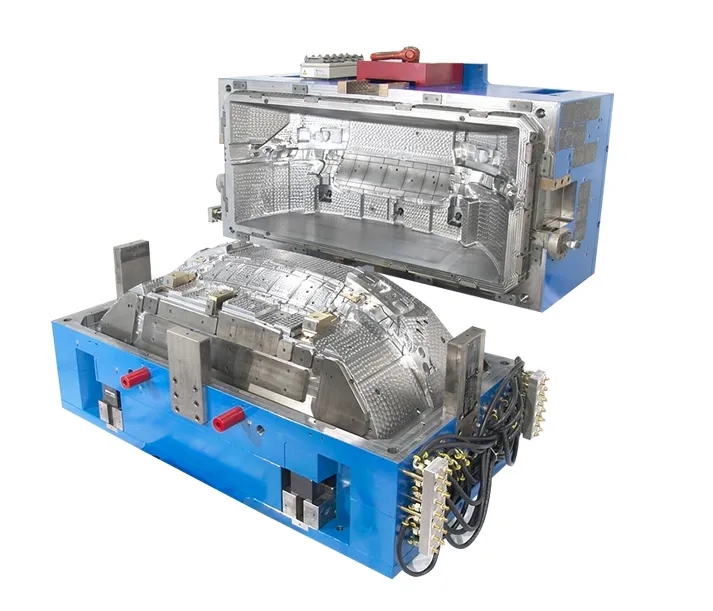

Injection moulding methods for automotive parts

The increasing demands on automotive plastic parts and the speed at which automotive moulds are being developed at ever lower costs are forcing manufacturers of automotive plastic parts to develop and adopt new production processes. Injection moulding is the most important technology for the prod...Read more -

Process differences between 3D printing and traditional CNC

Originally created as a method of rapid prototyping, 3D printing, also known as additive manufacturing, has evolved into a true manufacturing process. 3D printers enable engineers and companies to produce both prototype and end-use products at the same time, offering significant advantages over t...Read more -

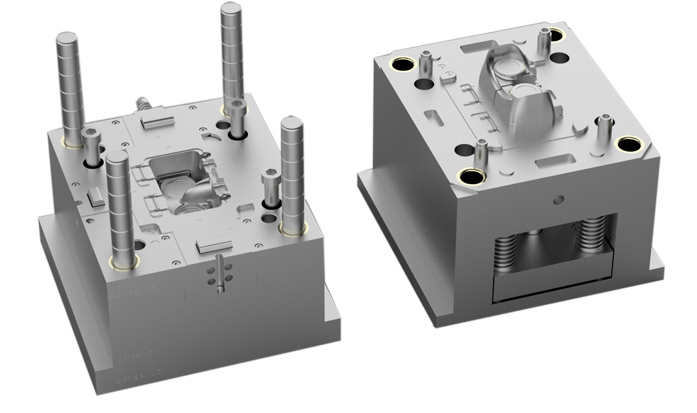

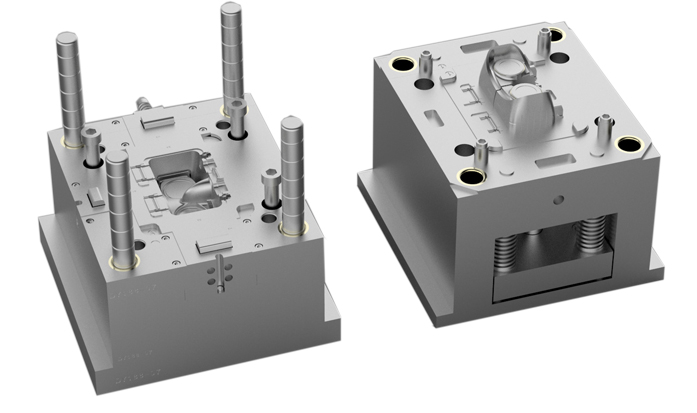

What is the difference between injection moulds and die-casting moulds?

When it comes to moulds, people often associate die-casting moulds with injection moulds, but in fact the difference between them is still very significant. As die casting is the process of filling a mould cavity with liquid or semi-liquid metal at a very high rate and solidifying it under pressu...Read more -

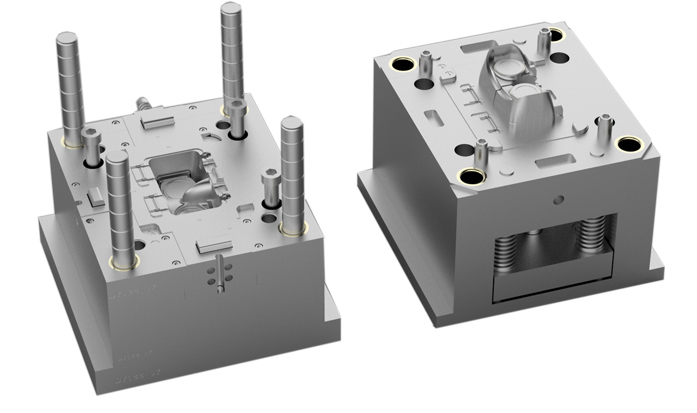

How to design the flow channel of precision injection moulds?

(1) Key points in the design of the main flow path of a precision injection mould The diameter of the main flow channel affects the pressure, flow rate and mould filling time of the molten plastic during injection. In order to facilitate the processing of precision injection moulds, the main flow...Read more -

Why is it necessary to heat the mold?

Plastic molds are common tools for producing plastic products, and many people want to know why it is necessary to heat the molds during the process. First of all, mold temperature affects the appearance quality,shrinkage, injection cycle and deformation of the product. High or low mold te...Read more -

How to maintain the injection moulds?

Whether a mould is good or not, in addition to the quality of the mold itself, maintenance is also the key to extend the mould life.Injection mold maintenance includes: pre-production mold maintenance, production mold maintenance, downtime mold maintenance. First, pre-production mold maintenance ...Read more -

What are the applications and characteristics of silicone molds?

Silicone mold, also known as vacuum mold, refers to using the original template to make a silicone mold in a vacuum state, and pouring it with PU, silicone, nylon ABS and other materials in a vacuum state, so as to clone the original model. The replica of the same model, the restoration rate reac...Read more -

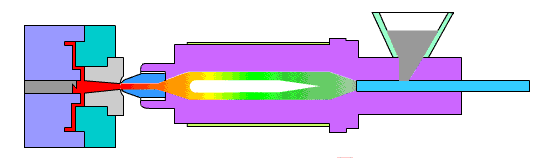

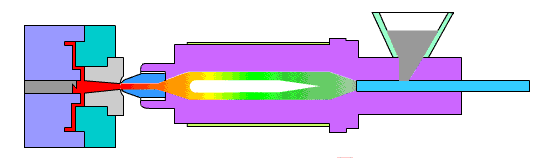

What are the steps in the injection molding process?

In our daily life, each of us uses products involving injection molding applications on a daily basis. The basic manufacturing process of injection molding is not complicated, but the requirements for product design and equipment are relatively high. The raw material is usually granular plastic. ...Read more -

How is the plastic injection mold processed to produce plastic products?

Since human beings have entered the industrial society, the production of all kinds of products have gotten rid of manual work, automated machine production has been popular in all walks of life, and the production of plastic products is no exception, nowadays, plastic products are processed by i...Read more -

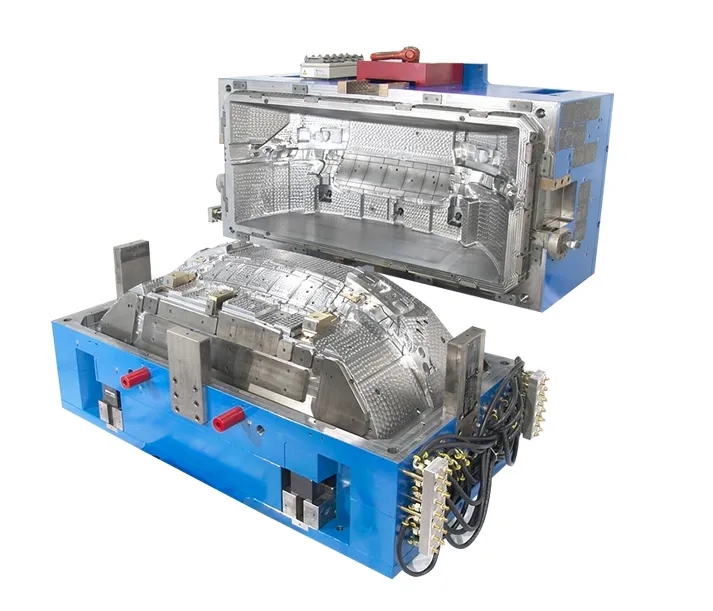

Do you know the categories of automotive plastic moulds?

There are many ways to classify automotive plastic moulds, according to the different methods of plastic parts forming and processing, they can be divided into the following categories. 1 – Injection mold The molding process of injection mold is characterized by placing the plastic material...Read more

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur