-

Thin-walled auto parts and Injection molding process

In recent years, replacing steel with plastic has become an inevitable means of lightweighting automobiles. For example, large parts such as fuel tank caps and front and rear bumpers made of metal in the past are now instead of plastic. Among them, automotive plastic in developed countries have a...Read more -

Injection molding of PMMA material

PMMA material is commonly known as plexiglass, acrylic, etc. The chemical name is polymethyl methacrylate. PMMA is a non-toxic and environmental friendly material. The biggest feature is high transparency, with a light transmittance of 92%. The one with the best light properties, the UV transmitt...Read more -

Plastic molding knowledge in the injection molding industry

Injection molding, simply speaking, is a process of using metal materials to form a cavity in the shape of a part, applying pressure to molten fluid plastic to inject it into the cavity and maintaining the pressure for a period of time, and then cooling the plastic melt and taking out the finishe...Read more -

Several methods about mold polishing

With the wide application of plastic products, the public has higher and higher requirements for the appearance quality of plastic products, so the surface polishing quality of the plastic mold cavity should also be improved accordingly, especially the mold surface roughness of the mirror surface...Read more -

The difference between plastic mold and die casting mold

Plastic mold is an abbreviation for a combined mold for compression molding, extrusion molding, injection molding, blow molding and low foam molding. Die-casting die is a method of casting liquid die forging, a process completed on a dedicated die-casting die forging machine. So what is the diffe...Read more -

The application of 3D printing technology in the field of automobile manufacturing

During these years, the most natural way for 3D printing to enter the automotive industry is rapid prototyping. From car interior parts to tires, front grilles, engine blocks, cylinder heads, and air ducts, 3D printing technology can create prototypes of almost any auto part. For automotive compa...Read more -

Injection molding process of home appliance plastic products

In recent years, some new plastic processing technologies and new equipment have been widely used in the molding of home appliance plastic products, such as precision injection molding, rapid prototyping technology and lamination injection molding technology etc. Let’s talk about the three ...Read more -

Detailed explanation of ABS plastic injection molding process

ABS plastic occupies an important position in the electronics industry, machinery industry, transportation, building materials, toy manufacturing and other industries due to its high mechanical strength and good comprehensive performance, especially for slightly larger box structures and stress c...Read more -

Some tips about choosing plastic molds

As you all know,plastic mold is the abbreviation of a combined mold,which covers compression molding, extrusion molding, injection molding, blow molding and low foam molding. The coordinated changes of the mold convex, concave mold and auxiliary molding system,we can process a series of plastic p...Read more -

PCTG & plastic ultrasonic welding

Poly Cyclohexylenedimethylene Terephthalate glycol-modified, otherwise known as PCT-G plastic is a clear co-polyester. PCT-G polymer is particularly suited for applications requiring very low extractables, high clarity and very high gamma stability. The material is also characterised by high impa...Read more -

The injection molding products in the daily life

All products molded by injection molding machines are injection molded products. Including thermoplastic and now some thermo set injection molding products. One of the most significant features of thermoplastic products is that the raw materials can be repeatedly injected, but some physical and c...Read more -

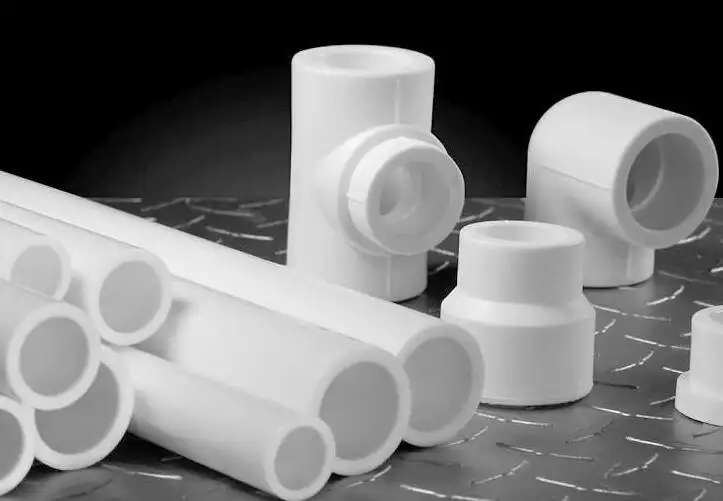

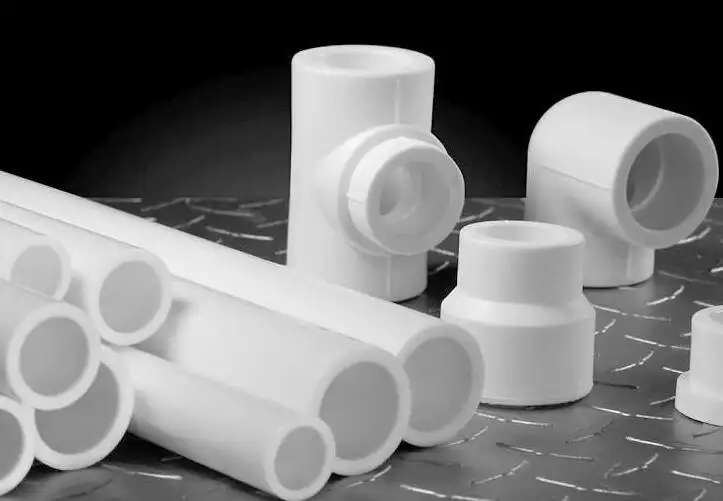

Injection molding of PP material

Polypropylene (PP) is a thermoplastic “addition polymer” made from the combination of propylene monomers. It is used in a variety of applications to include packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like living hinges,...Read more

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur