We always believe that one’s character decides products’ quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Factory Cheap Hot China Safety Helmet Plastic Injection Factory Protect Helmets Cover Molding Housing, We’ll empower people by communicating and listening, Setting an example to others and learning from experience.

We always believe that one’s character decides products’ quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for China Safety Helmet Plastic Cover Housing Molding, Motorcycle Helmet Injection Mold, Our mission is “Provide Goods with Reliable Quality and Reasonable Prices”. We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

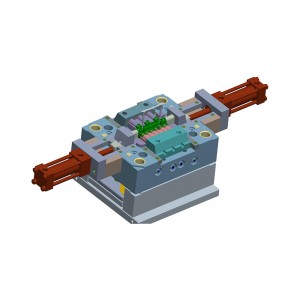

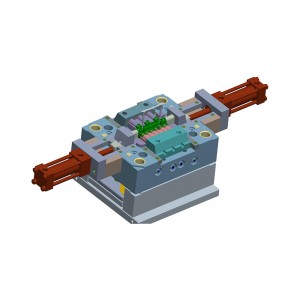

ABS + PC combines the excellent characteristics of the two materials. The Synthetic material is suitable for the housing of electronic products, with good overall performance, high impact strength, chemical stability, and electrical properties.

This is a smart doorbell product. The appearance requirements must be very attractive to customers. The drawing texture is made on the mold; in the injection molding production process, there should be no oil responsibility on the mold surface. The robot is automatically produced, and the operator packs early. You must wear dust-free gloves to avoid the sweat from your hands sticking to the product. If there is oil responsibility, it will directly affect the adhesion of the electroplating.

This brushing surface was made by mold texture.

Basemap production→photographic platemaking→screen printing→ink blending→decal paper printing decorative pattern→ink drying→mold pre-treatment→decal transfer→drying→repairing→corrosion→inspection→cleaning and anti-rust.

Process principle and process of mold surface corrosion skin texture:

Mold etching adopts anti-corrosion transfer ink, screen printing decorative pattern on decal paper, and transfer the decorative pattern ink to the mold with filming method. After drying and trimming, chemical corrosion is performed to form bumps on the mold. Type decorative pattern.

That’s the introduction of this product, if you have similar design need to make prototyping or mold, warmly welcome to contact us at any time.

We always believe that one’s character decides products’ quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Factory Cheap Hot China Safety Helmet Plastic Injection Factory Protect Helmets Cover Molding Housing, We’ll empower people by communicating and listening, Setting an example to others and learning from experience.

Factory Cheap Hot China Safety Helmet Plastic Cover Housing Molding, Motorcycle Helmet Injection Mold, Our mission is “Provide Goods with Reliable Quality and Reasonable Prices”. We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Send your message to us:

-

Big discounting China Professional Plastic Mold...

-

OEM/ODM Supplier China Waterproof Smart Metal S...

-

Good quality China Customized Car Motor Gear ...

-

Excellent quality China Plastic Overmolds Plast...

-

New Delivery for China Customized Plastic High ...

-

Good quality China Customized Car Motor Gear ...