Quality First,and Client Supreme is our guideline to deliver the very best assistance to our shoppers.These days, we have been trying our greatest to be amongst the ideal exporters inside our field to fulfill consumers extra will need for Free sample for China CNC Precision Machining Parts for Store, Store Mold, Supermarket, Workshop, Garage Plastic Shelf Parts, Our Lab now is “National Lab of diesel engine turbo technology ” , and we own a qualified R&D staff and complete testing facility.

Quality First,and Client Supreme is our guideline to deliver the very best assistance to our shoppers.These days, we have been trying our greatest to be amongst the ideal exporters inside our field to fulfill consumers extra will need for China Plastic Shelf Parts, Custom Plastic Shelf Parts, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we’re about to create”the reputable international brand of nylon monofilaments”, and spreading our solutions to every corner of the world. We’ve been keep moving and try our best to serve our customers.

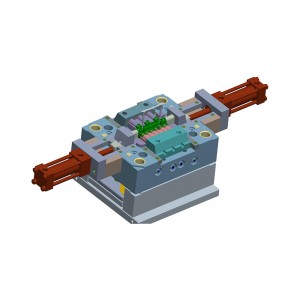

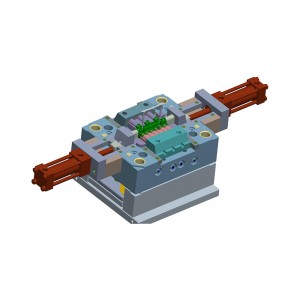

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.Quality First,and Client Supreme is our guideline to deliver the very best assistance to our shoppers.These days, we have been trying our greatest to be amongst the ideal exporters inside our field to fulfill consumers extra will need for Free sample for China CNC Precision Machining Parts for Store, Store Mold, Supermarket, Workshop, Garage Plastic Shelf Parts, Our Lab now is “National Lab of diesel engine turbo technology ” , and we own a qualified R&D staff and complete testing facility.

Free sample for China Plastic Shelf Parts, Custom Plastic Shelf Parts, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we’re about to create”the reputable international brand of nylon monofilaments”, and spreading our solutions to every corner of the world. We’ve been keep moving and try our best to serve our customers.

Send your message to us:

-

Chinese wholesale China High Quality Blow Moldi...

-

Chinese wholesale China High Quality Blow Moldi...

-

Price Sheet for China High Quality Plastic Hous...

-

Good quality China Customized Car Motor Gear ...

-

Excellent quality China Plastic Overmolds Plast...

-

Good quality China Customized Car Motor Gear ...