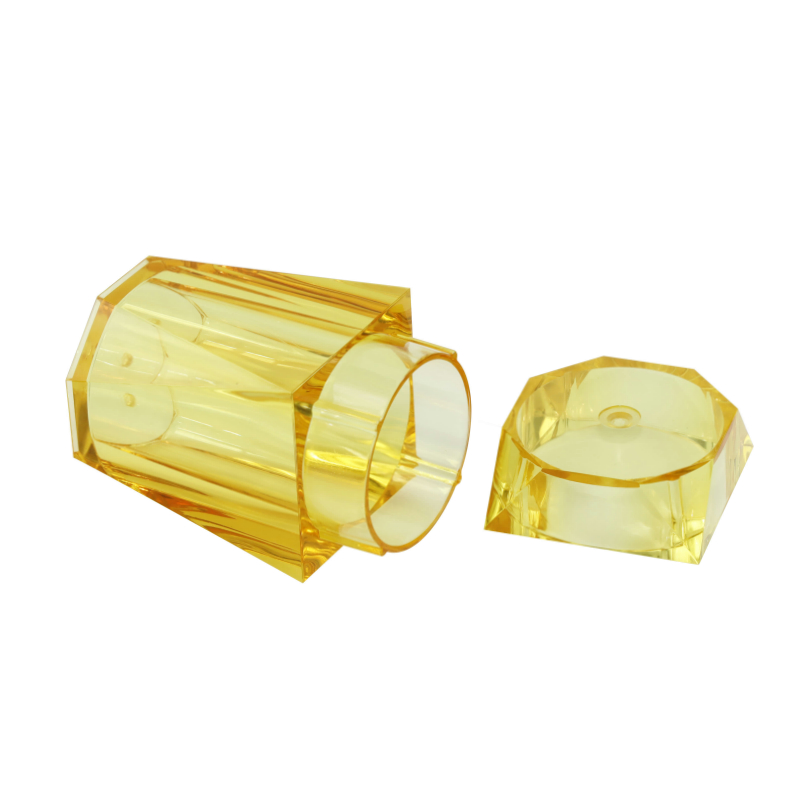

Good quality Die Casting - Customized FDA Grade Injection Moulding PS Transparentplastic Bottle – DTG Detail:

Polystyrene has good fluidity, good processing properties, easy coloring, and good dimensional stability. It can be processed into various parts by injection molding, extrusion, foaming, thermoforming, bonding, coating, welding, machining, printing and other methods, especially suitable for injection molding. It can be recycled, does not contain harmful substances, has no peculiar smell, no pollution, and is environmentally friendly. Suitable for daily necessities, drinking cold water cups, etc., transparent buttons, lampshades, etc. of household appliances are widely used.

This is a functional cup with a dust-proof cover and a cup body. The objects inside can be seen with 70% transparency. The pentagonal design and amber color show its uniqueness. There is no injection molding production. Oil stains, the perfect hidden latent glue port is not easy to be found. The push plate thimble structure avoids the appearance of thimble marks. Wear gloves during the production process, and PE belts are individually wrapped to avoid scratches.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Good quality Die Casting - Customized FDA Grade Injection Moulding PS Transparentplastic Bottle – DTG, The product will supply to all over the world, such as: Comoros, Lithuania, Montreal, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.