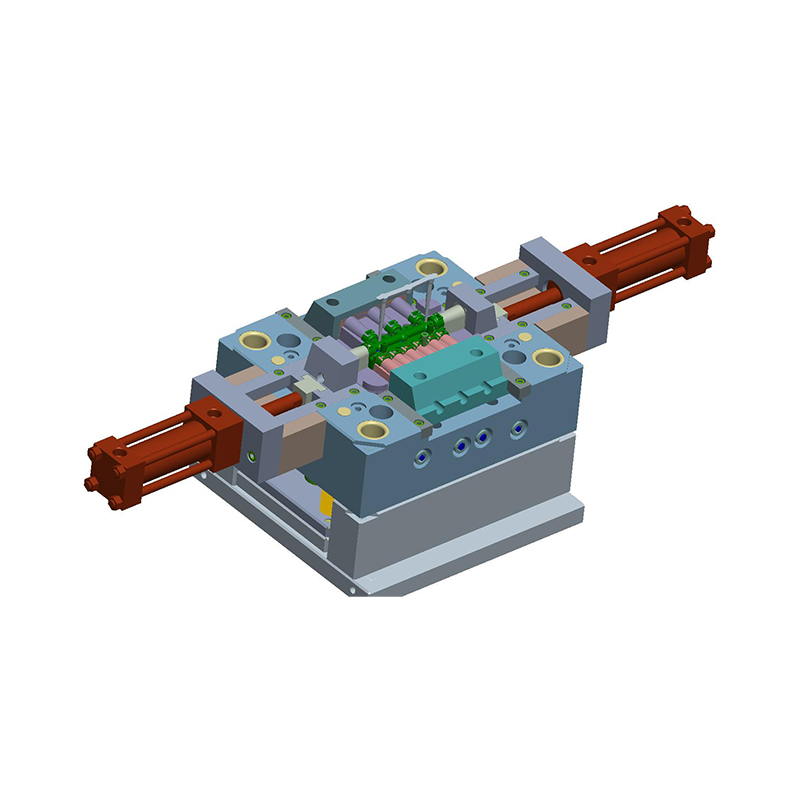

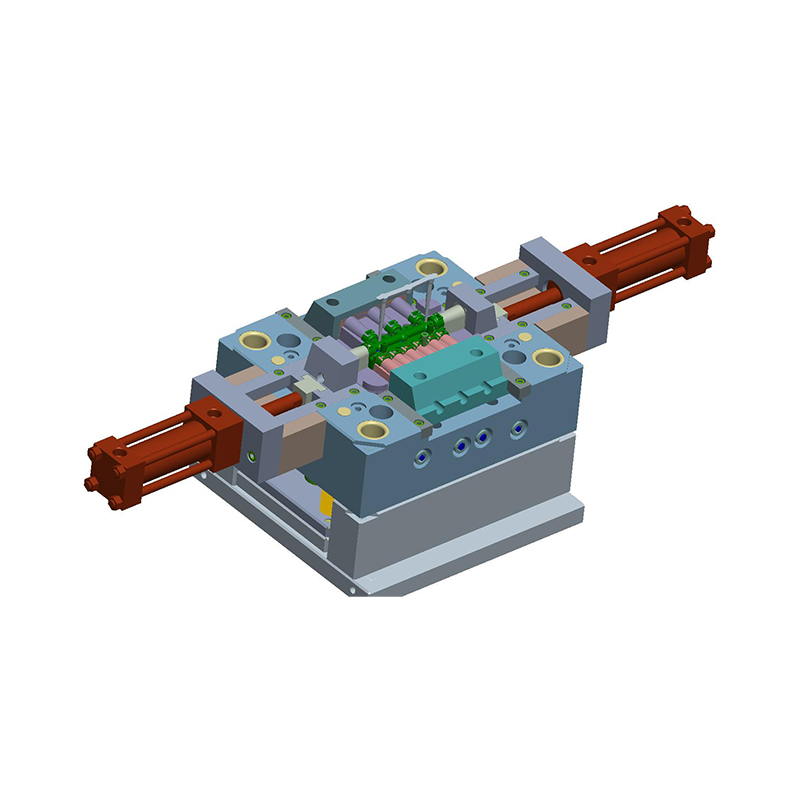

Good quality Lightweight Injection Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG Detail:

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for Good quality Lightweight Injection Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG, The product will supply to all over the world, such as: Jamaica, Nepal, Bahrain, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Send your message to us:

-

New Arrival China Injection Molds - OEM high ...

-

Top Suppliers Plastic Crafts - OEM PC+PP Car A...

-

OEM Manufacturer Rubber Moulds - Professional ...

-

Factory wholesale Plastic Injection Bottle Cap ...

-

Massive Selection for Acrylic Cosmetic Box Moul...

-

Quality Inspection for Skateboard Mould - Prof...