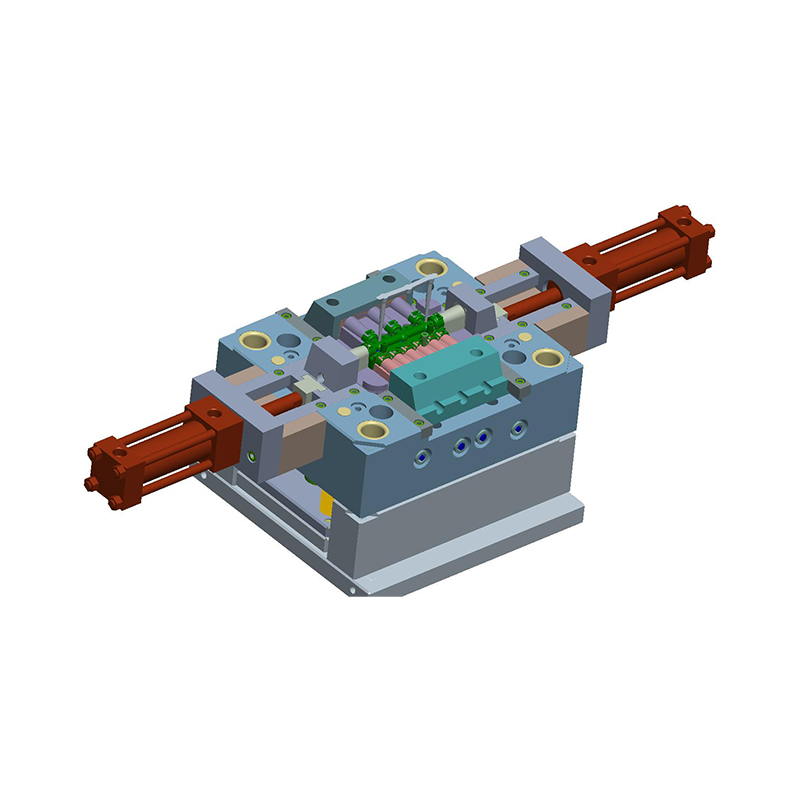

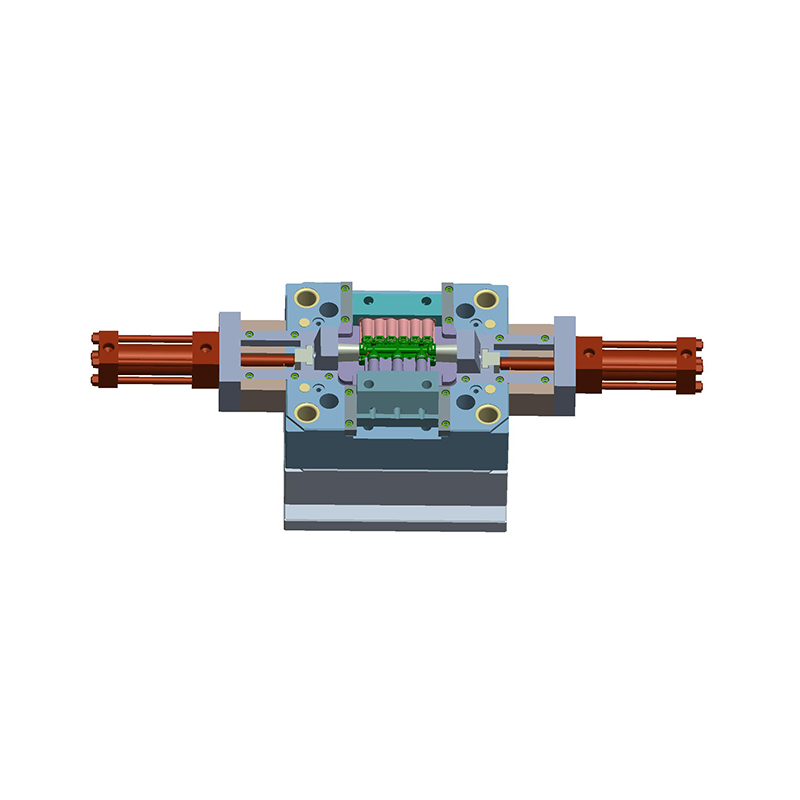

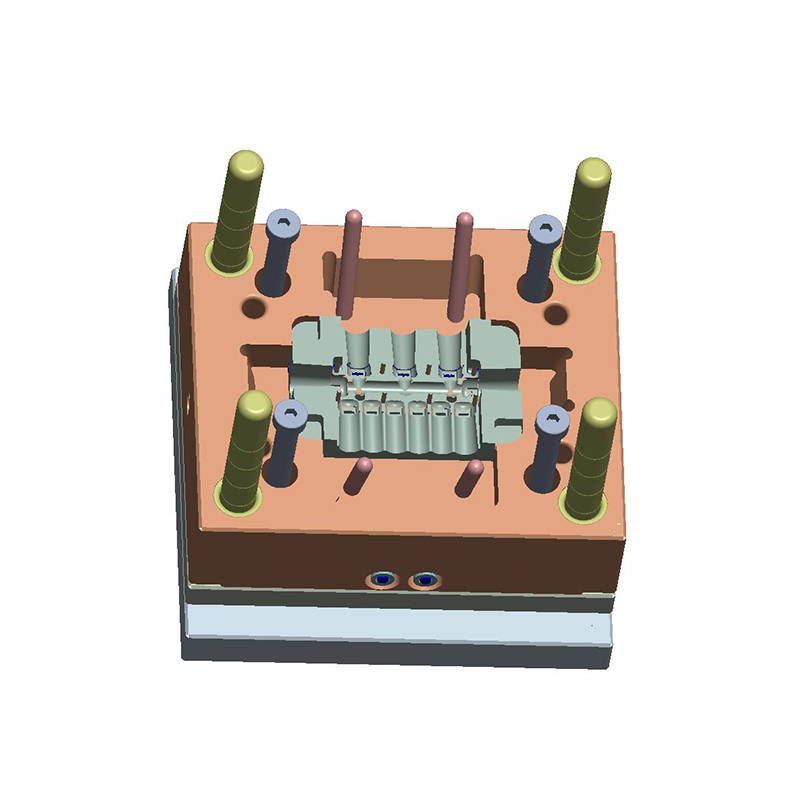

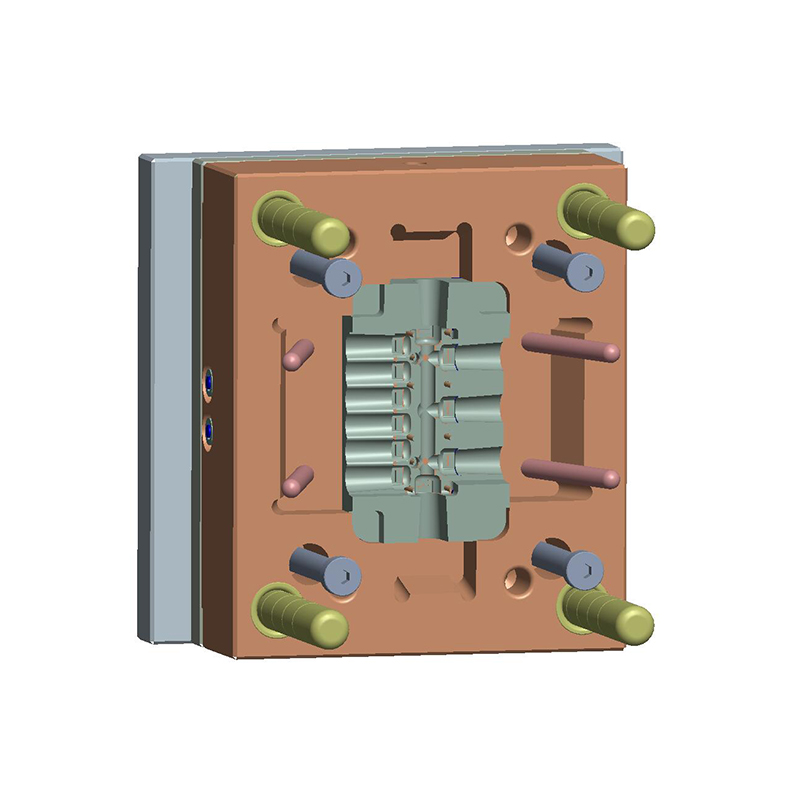

High Quality for Precision Mold Components - OEM high grade plastic injection mold of multifunctional connector – DTG Detail:

The function of heat treatment of mold materials is to improve the mechanical properties of materials, eliminate residual stress and improve the machinability of metals. Its heat treatment processes include annealing, normalizing, quenching and tempering. Finally, the purpose of heat treatment is to improve the mechanical properties such as hardness, wear resistance and strength, which can improve the strength and service life of the mold.

The mold is designed with a 3-plate mold structure. The A-plate automatically falls off the material head. The material head and products can be produced automatically by manipulator. The core and cavity are designed with 4 groups of cooling system, which is suitable for the production of 160t injection molding machine. The left and right sliders are equipped with two oil cylinders with a stroke of 80mm. It works synchronously with the other two sliders when opening the mold, and core have ejector pin to help eject.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for High Quality for Precision Mold Components - OEM high grade plastic injection mold of multifunctional connector – DTG, The product will supply to all over the world, such as: Poland, Atlanta, Haiti, We have to continue to uphold the quality, comprehensive, efficient business philosophy of honest, responsible, innovativespirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.