Ua raws li koj lub hauv paus ntsiab lus ntawm "zoo, kev pab, kev ua tau zoo thiab kev loj hlob", peb tau txais kev ntseeg siab thiab qhuas los ntawm cov neeg siv khoom hauv tsev thiab thoob ntiaj teb rau Cov Khoom Siv Zoo Tshaj Plaws Tuam Tshoj Yas Txhaj Tshuaj Txhaum Txhaum Txhaj Tshuaj Txhaj Tshuaj Moulding, Thiab peb tuaj yeem pab nrhiav txhua yam khoom ntawm cov neeg siv khoom xav tau. Nco ntsoov muab kev pabcuam zoo tshaj plaws, Qhov Zoo Tshaj Plaws, Kev xa khoom sai.

Ua raws li koj lub hauv paus ntsiab lus ntawm "zoo, kev pab, kev ua tau zoo thiab kev loj hlob", peb tau txais kev ntseeg siab thiab kev qhuas los ntawm cov neeg siv khoom hauv tsev thiab thoob ntiaj teb rauTuam Tshoj Overmold, Txhaj Molding, "Tsim muaj nuj nqis, Pab cov neeg siv khoom!" yog lub hom phiaj peb caum. Peb ua tsaug cia siab tias txhua tus neeg siv khoom yuav tsim lub sijhawm ntev thiab muaj txiaj ntsig kev koom tes nrog peb.Yog tias koj xav tau cov ntsiab lus ntxiv txog peb lub tuam txhab, Nco ntsoov tiv tauj peb tam sim no!

Kev ua haujlwm ntawm kev kho cua sov ntawm cov ntaub ntawv pwm yog txhawm rau txhim kho cov khoom siv kho tshuab ntawm cov ntaub ntawv, tshem tawm cov kev ntxhov siab seem thiab txhim kho machinability ntawm cov hlau. Nws cov txheej txheem kho cua sov muaj xws li annealing, normalizing, quenching thiab tempering. Thaum kawg, lub hom phiaj ntawm kev kho cua sov yog los txhim kho cov khoom siv xws li hardness, hnav tsis kam thiab lub zog, uas tuaj yeem txhim kho lub zog thiab kev pabcuam lub neej ntawm pwm.

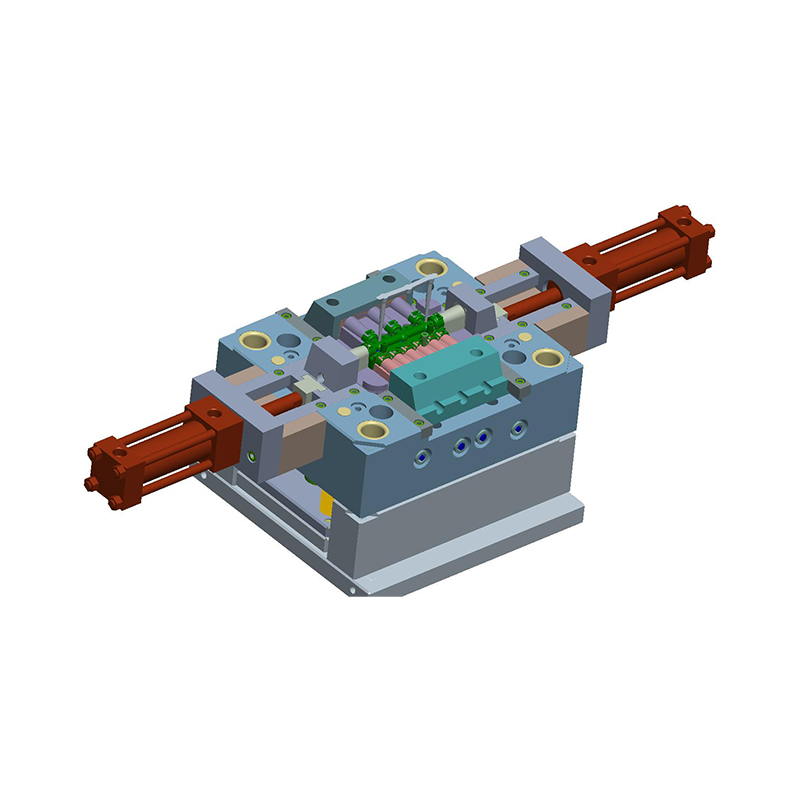

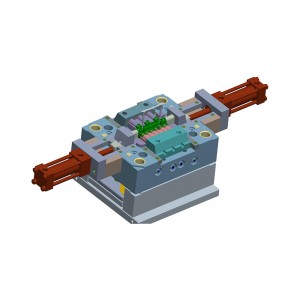

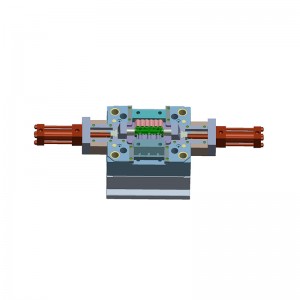

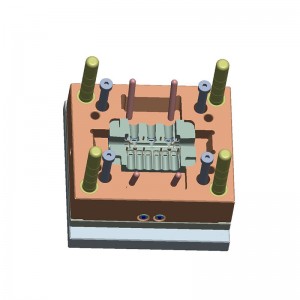

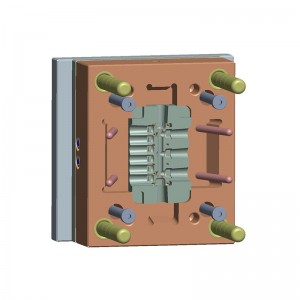

Cov pwm yog tsim los nrog 3-phaj pwm qauv. Lub A-phaj cia li poob ntawm cov khoom siv lub taub hau. Cov khoom siv lub taub hau thiab cov khoom tuaj yeem tsim tau los ntawm kev tswj xyuas. Cov tub ntxhais thiab kab noj hniav yog tsim los nrog 4 pawg ntawm cov cua txias, uas yog tsim rau kev tsim 160t txhaj tshuaj molding tshuab. Sab laug thiab sab xis sliders yog nruab nrog ob lub tog raj kheej roj nrog lub stroke ntawm 80mm. Nws ua hauj lwm synchronously nrog rau lwm ob sliders thaum qhib lub pwm, thiab cov tub ntxhais muaj ejector tus pin los pab eject.

| DTG Mould Trade Txheej txheem | |

| Nqe lus | Raws li cov qauv, kos duab thiab cov kev xav tau tshwj xeeb. |

| Kev sib tham | Cov khoom siv pwm, kab noj hniav naj npawb, nqe, khiav, kev them nyiaj, thiab lwm yam. |

| S/C Kos Npe | Kev pom zoo rau txhua yam khoom |

| Ua ntej | Them 50% los ntawm T / T |

| Cov khoom tsim kuaj xyuas | Peb xyuas cov khoom tsim. Yog tias qee txoj haujlwm tsis zoo tag nrho, lossis tsis tuaj yeem ua tiav ntawm cov pwm, peb yuav xa cov neeg siv daim ntawv tshaj tawm. |

| Pwm Tsim | Peb ua pwm tsim los ntawm kev paub tseeb cov khoom tsim, thiab xa mus rau cov neeg siv khoom kom paub meej. |

| Pwm Tooling | Peb pib ua pwm tom qab pwm tsim paub meej |

| Kev ua pwm | Xa daim ntawv tshaj tawm rau cov neeg siv khoom ib zaug txhua lub lim tiam |

| Kev kuaj pwm | Xa cov qauv sim thiab sim-tawm qhia rau cov neeg siv khoom kom paub meej |

| Pwm Hloov | Raws li cov neeg siv khoom tawm tswv yim |

| Sib npaug | 50% los ntawm T / T tom qab tus neeg siv khoom pom zoo cov qauv sim thiab pwm zoo. |

| Kev xa khoom | Kev xa khoom los ntawm hiav txwv lossis huab cua. Tus neeg xa xov tuaj yeem raug xaiv los ntawm koj sab. |

Kev Muag Khoom

Kev muag khoom ua ntej:

Peb lub tuam txhab muab cov neeg muag khoom zoo rau kev tshaj lij thiab kev sib txuas lus sai.

Hauv kev muag khoom:

Peb muaj cov neeg tsim qauv tsim muaj zog, yuav txhawb cov neeg siv khoom R & D, Yog tias tus neeg siv khoom xa tuaj rau peb cov qauv, peb tuaj yeem ua cov khoom kos duab thiab ua qhov kev hloov kho raws li tus neeg thov kev thov thiab xa mus rau cov neeg siv khoom kom pom zoo. Tsis tas li ntawd peb yuav ua raws li peb cov kev paub dhau los thiab kev paub los muab cov neeg siv khoom peb cov tswv yim thev naus laus zis.

Tom qab kev muag khoom:

Yog tias peb cov khoom muaj qhov teeb meem zoo thaum lub sijhawm lav, peb yuav xa koj dawb rau hloov cov khoom tawg; kuj yog tias koj muaj teeb meem hauv kev siv peb cov pwm, peb muab kev sib txuas lus rau koj.

Lwm Cov Kev Pabcuam

Peb ua qhov kev cog lus ntawm kev pabcuam raws li hauv qab no:

1. Lub sijhawm ua haujlwm: 30-50 hnub ua haujlwm

2.Design lub sij hawm: 1-5 hnub ua hauj lwm

3.Email teb: hauv 24 teev

4.Quotation: hauv 2 hnub ua haujlwm

5.Cov neeg siv khoom tsis txaus siab: teb hauv 12 teev

6. Kev pab hu xov tooj: 24H/7D/365D

7.Cov khoom seem: 30%, 50%, 100%, raws li qhov yuav tsum tau ua

8.Cov qauv dawb: raws li qhov yuav tsum tau ua

Peb lav muab qhov zoo tshaj plaws thiab ceev pwm kev pabcuam rau cov neeg siv khoom!

| 1 | Qhov zoo tshaj plaws tsim, sib tw nqi |

| 2 | 20 xyoo kev nplua nuj ua haujlwm ua haujlwm |

| 3 | Kev tshaj lij hauv kev tsim & ua cov pwm yas |

| 4 | Ib qho kev daws teeb meem |

| 5 | Raws sij hawm xa tuaj |

| 6 | Qhov zoo tshaj plaws kev pab cuam tom qab muag |

| 7 | Tshwj xeeb hauv hom yas txhaj tshuaj pwm. |

DTG-Koj qhov kev txhim khu kev qha yas pwm thiab tus qauv tsim khoom!

Ua raws li koj lub hauv paus ntsiab lus ntawm "zoo, kev pab, kev ua tau zoo thiab kev loj hlob", peb tau txais kev ntseeg siab thiab qhuas los ntawm cov neeg siv khoom hauv tsev thiab thoob ntiaj teb rau Cov Khoom Siv Zoo Tshaj Plaws Tuam Tshoj Yas Txhaj Tshuaj Txhaum Txhaum Txhaj Tshuaj Txhaj Tshuaj Moulding, Thiab peb tuaj yeem pab nrhiav txhua yam khoom ntawm cov neeg siv khoom xav tau. Nco ntsoov muab kev pabcuam zoo tshaj plaws, Qhov Zoo Tshaj Plaws, Kev xa khoom sai.

Zoo heev Tuam Tshoj Overmold, Txhaj Moulding, "Tsim muaj nuj nqis, Pab cov neeg siv khoom!" yog lub hom phiaj peb caum. Peb ua tsaug cia siab tias txhua tus neeg siv khoom yuav tsim lub sijhawm ntev thiab muaj txiaj ntsig kev koom tes nrog peb.Yog tias koj xav tau cov ntsiab lus ntxiv txog peb lub tuam txhab, Nco ntsoov tiv tauj peb tam sim no!

Xa koj cov lus rau peb:

-

High Performance Tuam Tshoj Rooj Teeb Ntxuam Xov tooj Hol ...

-

OEM Customized Tuam Tshoj Aluminium Extrusion CNC Ma ...

-

Tuam Tshoj lag luam wholesale Tuam Tshoj High Quality Tshuab Moldi ...

-

Cheapest Hoobkas Tuam Tshoj Motorcycle Spare Parts o ...

-

Precision Tuag Casting Cov Hlau Me Me ...

-

Rov qab tsim dua tshiab rau Tsim Pwm Rack Plhaub ABS ...