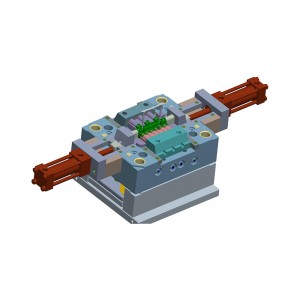

Cov neeg khiav dej kub kub siv lub taub hau taub hau uas tau noj los ntawm lub thoob siv lub twj tso kua mis, thaum cov neeg khiav dej txias siv lub kaw, thermoset pwm. Lub luag haujlwm tseem ceeb ntawm txhua qhov kev txhaj tshuaj khiav yog tswj cov khoom ntws los ntawm cov kab noj hniav mus rau cov kab noj hniav pwm. Lub kaw lus yuav tsum muaj lub siab ntxiv los thawb cov khoom los ntawm tus khiav.

Tus khiav kub ua rau nws yooj yim dua rau lub tshuab molding los txhaj cov yas rau hauv pwm kab noj hniav. Ib tug kub khiav nce lub peev xwm ntawm lub tshuab molding. Nws txo cov yas ntws ntev yog li lub molder tuaj yeem txuag cov khoom los ntawm kev ua kom nyias thiab sib dua

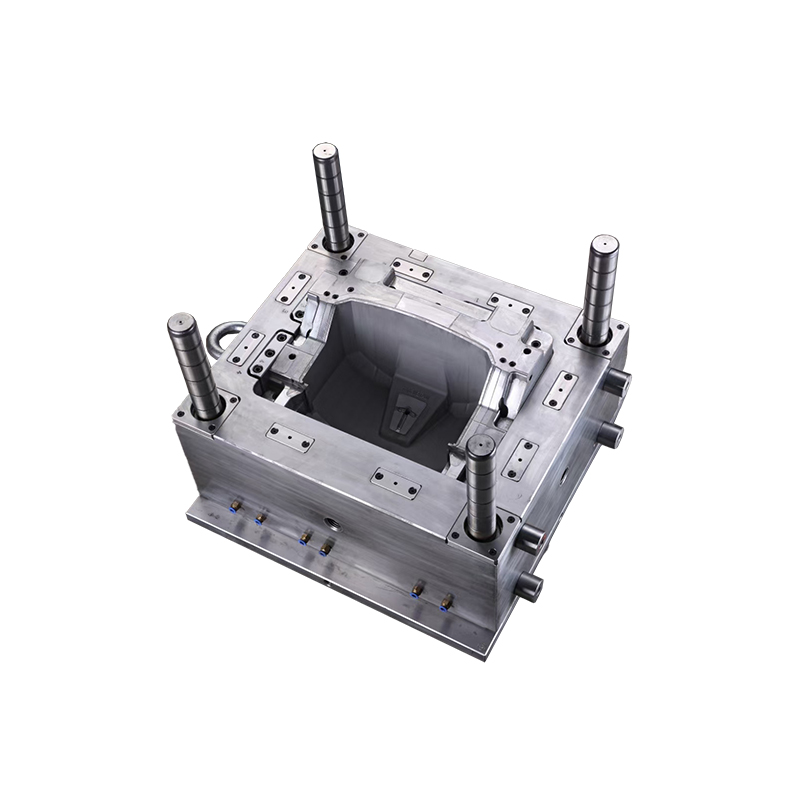

Cov pwm yog tsim los nrog AB board qauv thiab ejected los ntawm ejector tus pin. Nws tuaj yeem ua tau automated ntau lawm. Txoj kev kub khiav kev xa tawm thiab kev pub mis tuaj yeem ua rau luv luv ntawm kev txhaj tshuaj molding voj voog thiab txuag cov khoom yas ntawm tus khiav, yog li txo cov nqi, txhim kho cov khoom zoo thiab txo cov khoom pov tseg. Thaum lub sij hawm molding txheej txheem ntawm kub khiav pwm, qhov kub ntawm cov yas yaj yog raug tswj kom raug nyob rau hauv lub khiav khiav system. Kev tshem tawm cov txheej txheem rov qab yog qhov tsim nyog rau kev tsim khoom automation. Nthuav daim ntawv thov ntawm kev txhaj tshuaj molding tshuab.

| DTG Mould Trade Txheej txheem | |

| Nqe lus | Raws li cov qauv, kos duab thiab cov kev xav tau tshwj xeeb. |

| Kev sib tham | Cov khoom siv pwm, kab noj hniav naj npawb, nqe, khiav, kev them nyiaj, thiab lwm yam. |

| S/C Kos Npe | Kev pom zoo rau txhua yam khoom |

| Ua ntej | Them 50% los ntawm T / T |

| Cov khoom tsim kuaj xyuas | Peb xyuas cov khoom tsim. Yog tias qee txoj haujlwm tsis zoo tag nrho, lossis tsis tuaj yeem ua tiav ntawm cov pwm, peb yuav xa cov neeg siv daim ntawv tshaj tawm. |

| Pwm Tsim | Peb ua pwm tsim los ntawm kev paub tseeb cov khoom tsim, thiab xa mus rau cov neeg siv khoom kom paub meej. |

| Pwm Tooling | Peb pib ua pwm tom qab pwm tsim paub meej |

| Kev ua pwm | Xa daim ntawv tshaj tawm rau cov neeg siv khoom ib zaug txhua lub lim tiam |

| Kev kuaj pwm | Xa cov qauv sim thiab sim-tawm qhia rau cov neeg siv khoom kom paub meej |

| Pwm Hloov | Raws li cov neeg siv khoom tawm tswv yim |

| Sib npaug | 50% los ntawm T / T tom qab tus neeg siv khoom pom zoo cov qauv sim thiab pwm zoo. |

| Kev xa khoom | Kev xa khoom los ntawm hiav txwv lossis huab cua. Tus neeg xa xov tuaj yeem raug xaiv los ntawm koj sab. |

Kev Muag Khoom

Kev muag khoom ua ntej:

Peb lub tuam txhab muab cov neeg muag khoom zoo rau kev tshaj lij thiab kev sib txuas lus sai.

Hauv kev muag khoom:

Peb muaj cov neeg tsim qauv tsim muaj zog, yuav txhawb cov neeg siv khoom R & D, Yog tias tus neeg siv khoom xa tuaj rau peb cov qauv, peb tuaj yeem ua cov khoom kos duab thiab ua qhov kev hloov kho raws li tus neeg thov kev thov thiab xa mus rau cov neeg siv khoom kom pom zoo. Tsis tas li ntawd peb yuav ua raws li peb cov kev paub dhau los thiab kev paub los muab cov neeg siv khoom peb cov tswv yim thev naus laus zis.

Tom qab kev muag khoom:

Yog tias peb cov khoom muaj qhov teeb meem zoo thaum lub sijhawm lav, peb yuav xa koj dawb rau hloov cov khoom tawg; kuj yog tias koj muaj teeb meem hauv kev siv peb cov pwm, peb muab kev sib txuas lus rau koj.

Lwm Cov Kev Pabcuam

Peb ua qhov kev cog lus ntawm kev pabcuam raws li hauv qab no:

1. Lub sijhawm ua haujlwm: 30-50 hnub ua haujlwm

2.Design lub sij hawm: 1-5 hnub ua hauj lwm

3.Email teb: hauv 24 teev

4.Quotation: hauv 2 hnub ua haujlwm

5.Cov neeg siv khoom tsis txaus siab: teb hauv 12 teev

6. Kev pab hu xov tooj: 24H/7D/365D

7.Cov khoom seem: 30%, 50%, 100%, raws li qhov yuav tsum tau ua

8.Cov qauv dawb: raws li qhov yuav tsum tau ua

Peb lav muab qhov zoo tshaj plaws thiab ceev pwm kev pabcuam rau cov neeg siv khoom!

| 1 | Qhov zoo tshaj plaws tsim, sib tw nqi |

| 2 | 20 xyoo kev nplua nuj ua haujlwm ua haujlwm |

| 3 | Kev tshaj lij hauv kev tsim & ua cov pwm yas |

| 4 | Ib qho kev daws teeb meem |

| 5 | Raws sij hawm xa tuaj |

| 6 | Qhov zoo tshaj plaws kev pab cuam tom qab muag |

| 7 | Tshwj xeeb hauv hom yas txhaj tshuaj pwm. |