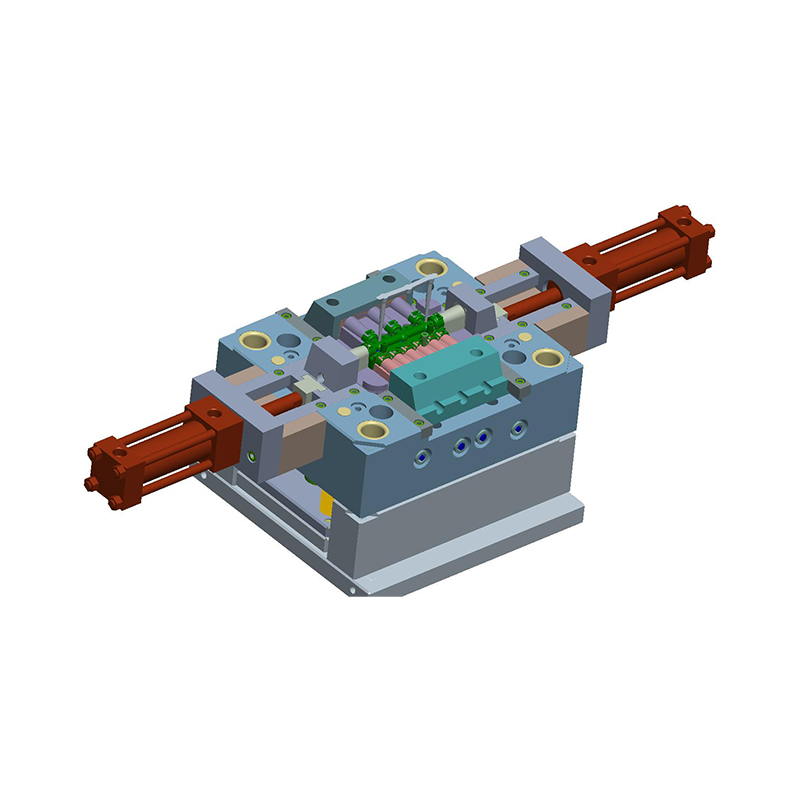

Hot New Products Customized Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG Detail:

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Hot New Products Customized Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG, The product will supply to all over the world, such as: Oslo , Detroit , Turkey , In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always offer customers support on products and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Send your message to us:

-

Reasonable price Casting Moulds - Customized P...

-

Factory Free sample Connector Mould - CNC Mach...

-

OEM Customized Plastic Injection Molding Proces...

-

Lowest Price for Auto Plastic Mould - Professi...

-

Chinese Professional Plastic Injection Mold Par...

-

China Supplier Plastic Fan Shell Mould - Custo...