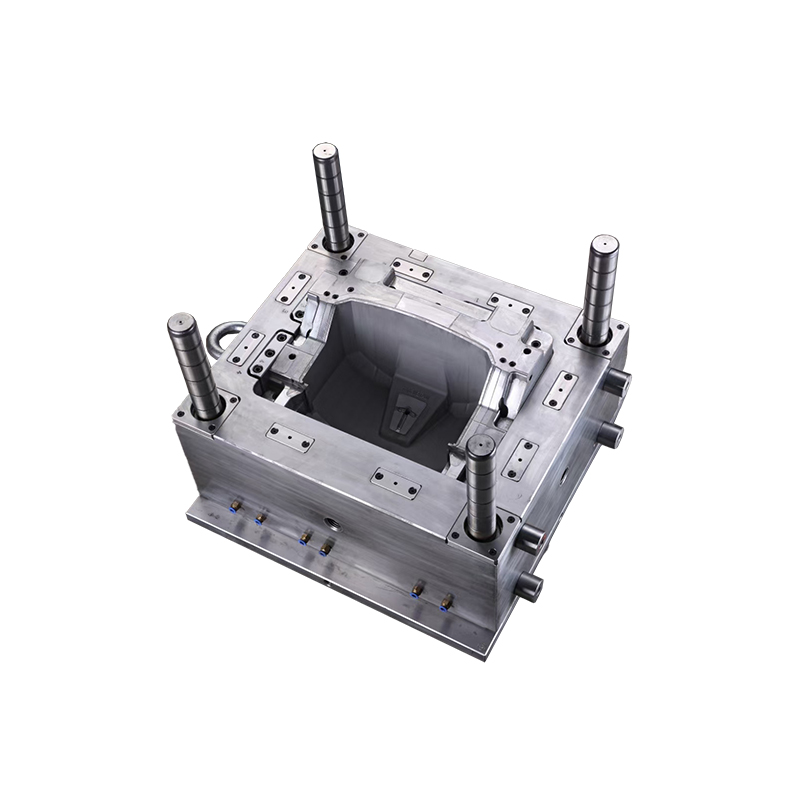

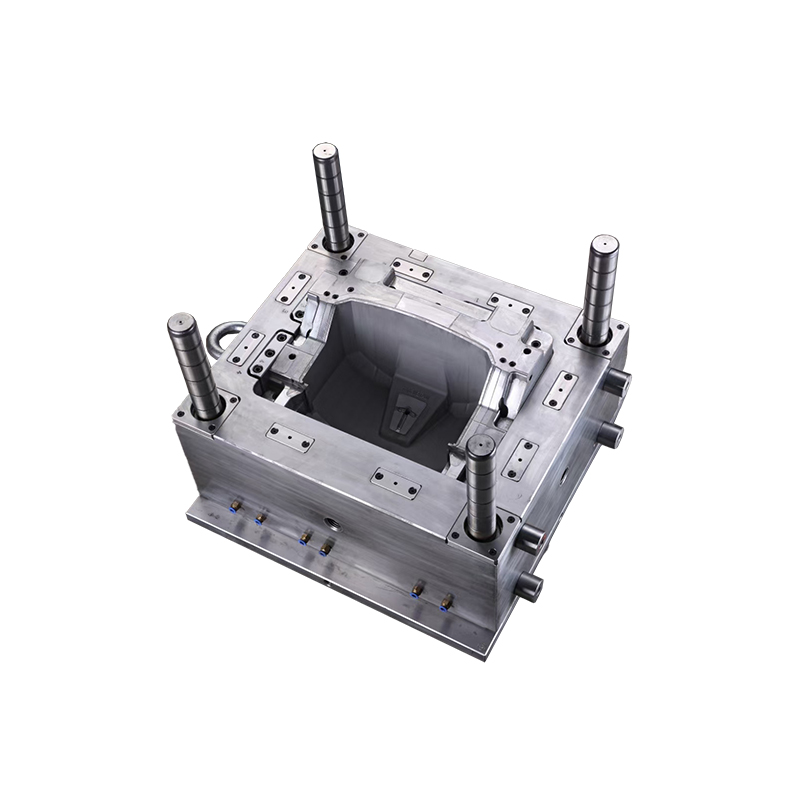

New Fashion Design for Plastic Home Appliance Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG Detail:

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for New Fashion Design for Plastic Home Appliance Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG, The product will supply to all over the world, such as: Costa rica, Egypt, Barbados, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Send your message to us:

-

Renewable Design for Bottle Cap Mould - Custom...

-

Cheap PriceList for Stainless Steel Housing - ...

-

Cheap PriceList for Precision Plastic Mold Comp...

-

High Quality Aluminum Die Casting Mold - China...

-

Factory Supply Plastic Mould Injection Molding ...

-

Wholesale Price Plastic Custom Mold - Customi...