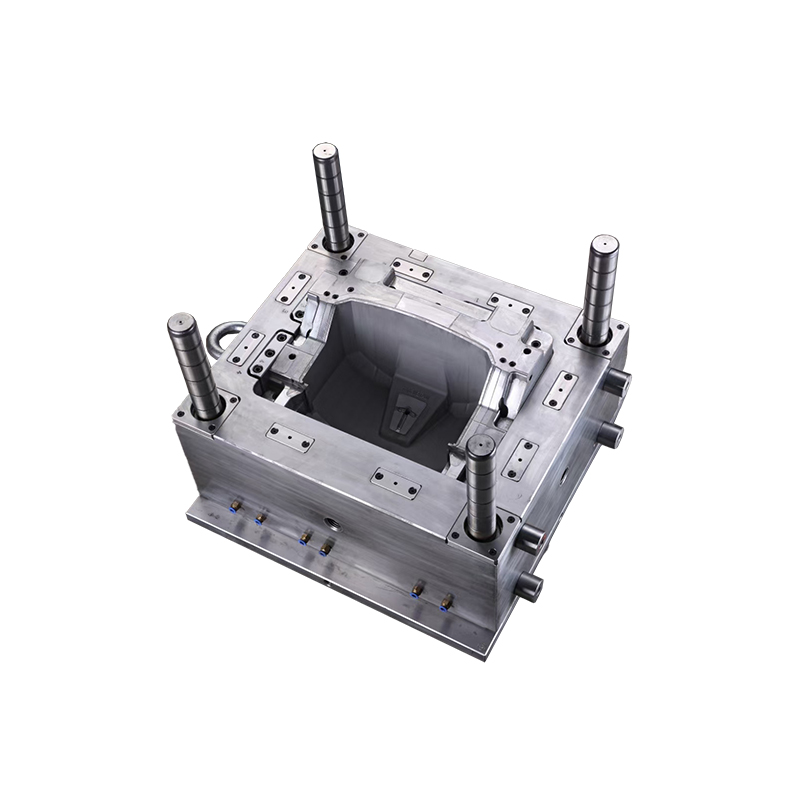

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we’ve been far more expert and more hard-working and do it in cost-effective way for ODM Manufacturer Chinese Manufacturer for Customized Plastic Mold or Injection Mold/Molding/Mould/Tooling Used for Auto Dashboard or Instrument Panel Plastic Parts, We consider in top quality more than quantity. Before export in the hair there is strict quality control check during treatment as per international excellent standards.

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we’ve been far more expert and more hard-working and do it in cost-effective way for China Injection Molding, Plastic Mould, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, make sure you contact us. And It is our great pleasure if you like to have a personally meeting in our office.

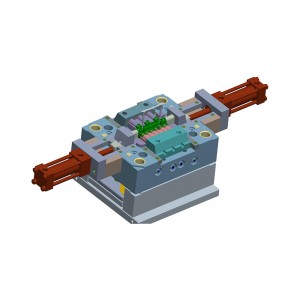

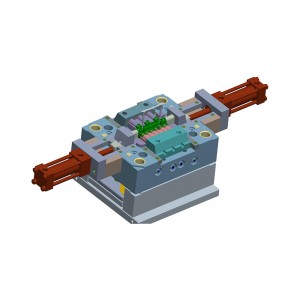

Hot runners use a screw nozzle that is fed by a barrel using a pump, while cold runners use a closed, thermoset mold. The primary task of any injection runner system is to direct the material flow from the sprue to the mold cavities. The system requires additional pressure to push the material through the runner.

A hot runner makes it easier for a molding machine to inject plastic into a mould cavity. A hot runner increases the capability of a molding machine. It reduces the plastic flow length so a molder can save material by making thinner and lighter parts

The mold is designed with AB board structure and ejected by ejector pin. It can be automated production. The hot runner dispensing and feeding method can shorten the injection molding cycle and save the plastic material of the runner, thereby reducing costs, improving product quality and reducing waste. During the molding process of the hot runner mold, the temperature of the plastic melt is accurately controlled in the runner system. Elimination of follow-up procedures is conducive to production automation. Expand the application of injection molding technology.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we’ve been far more expert and more hard-working and do it in cost-effective way for ODM Manufacturer Chinese Manufacturer for Customized Plastic Mold or Injection Mold/Molding/Mould/Tooling Used for Auto Dashboard or Instrument Panel Plastic Parts, We consider in top quality more than quantity. Before export in the hair there is strict quality control check during treatment as per international excellent standards.

ODM Manufacturer China Injection Molding, Plastic Mould, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, make sure you contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Send your message to us:

-

Cheapest Factory China Motorcycle Spare Parts o...

-

Excellent quality China Plastic Overmolds Plast...

-

Chinese wholesale China High Quality Blow Moldi...

-

Quality Inspection for China Aluminum Lampshade...

-

ODM Manufacturer China Plastic Washer protectio...

-

Personlized Products China Factory Plastic Prod...