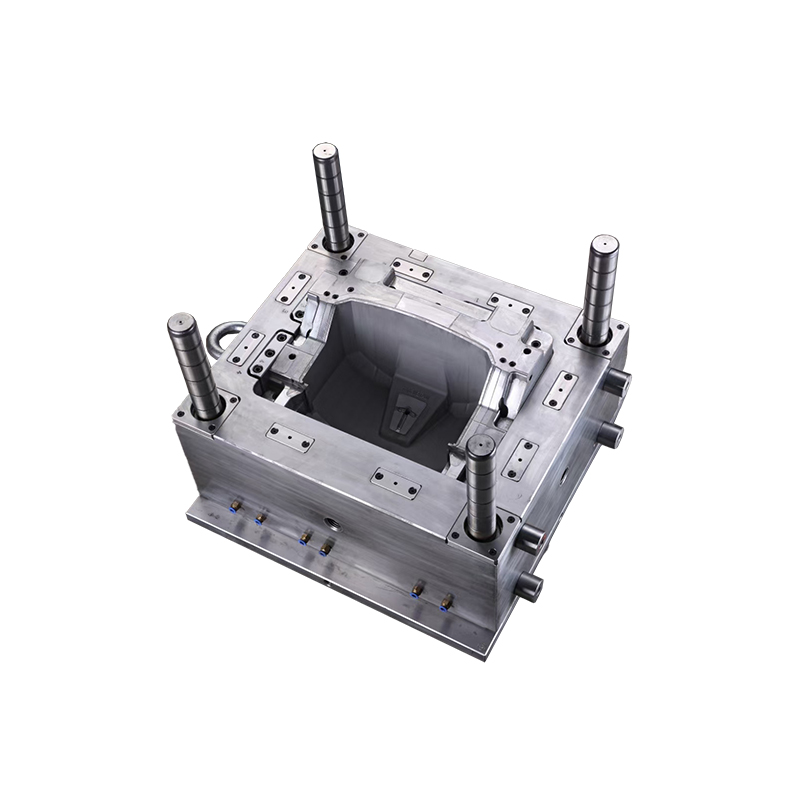

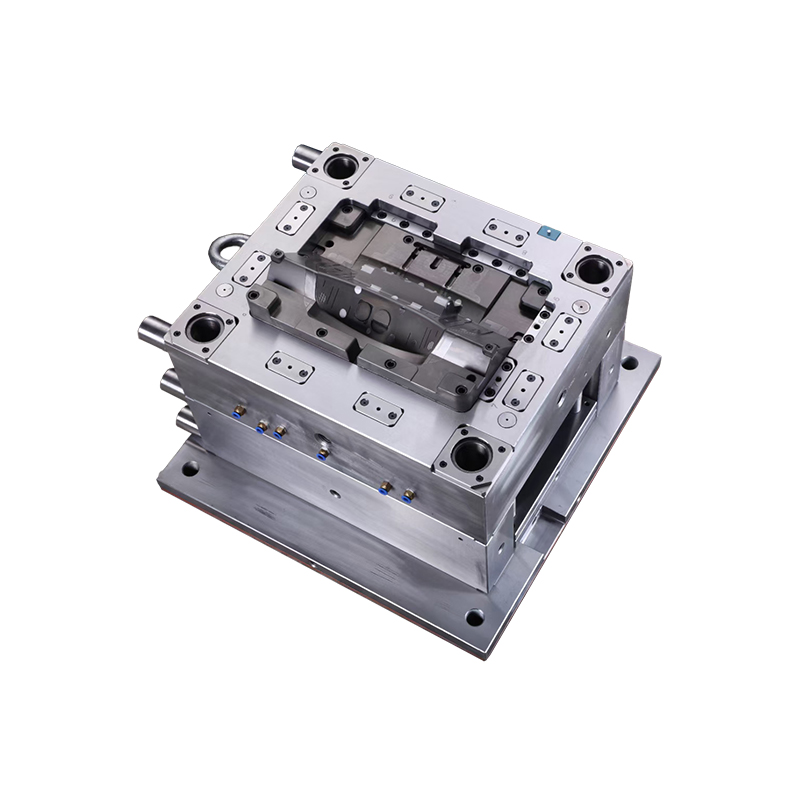

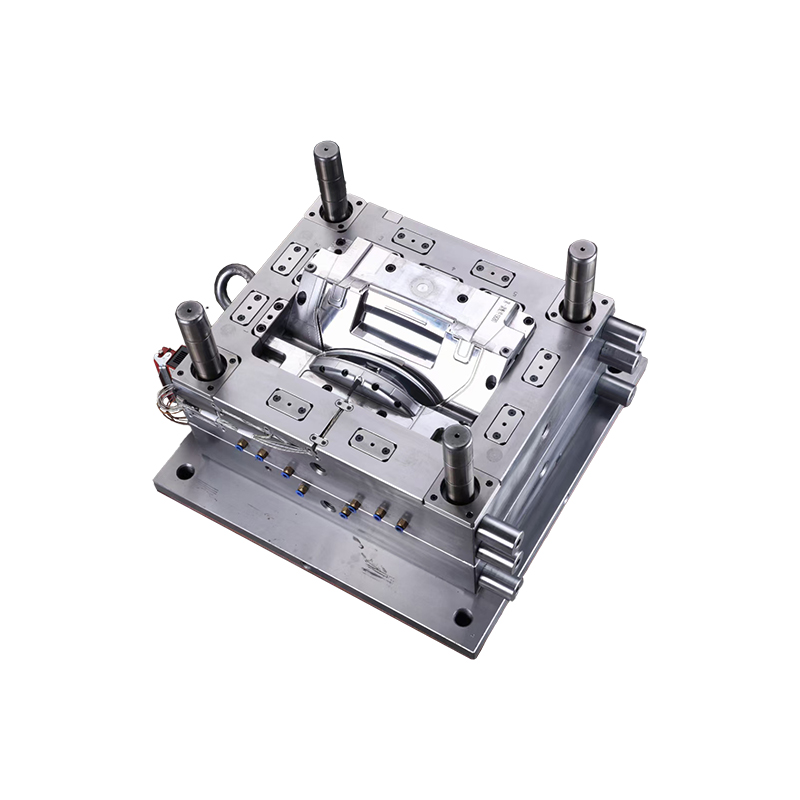

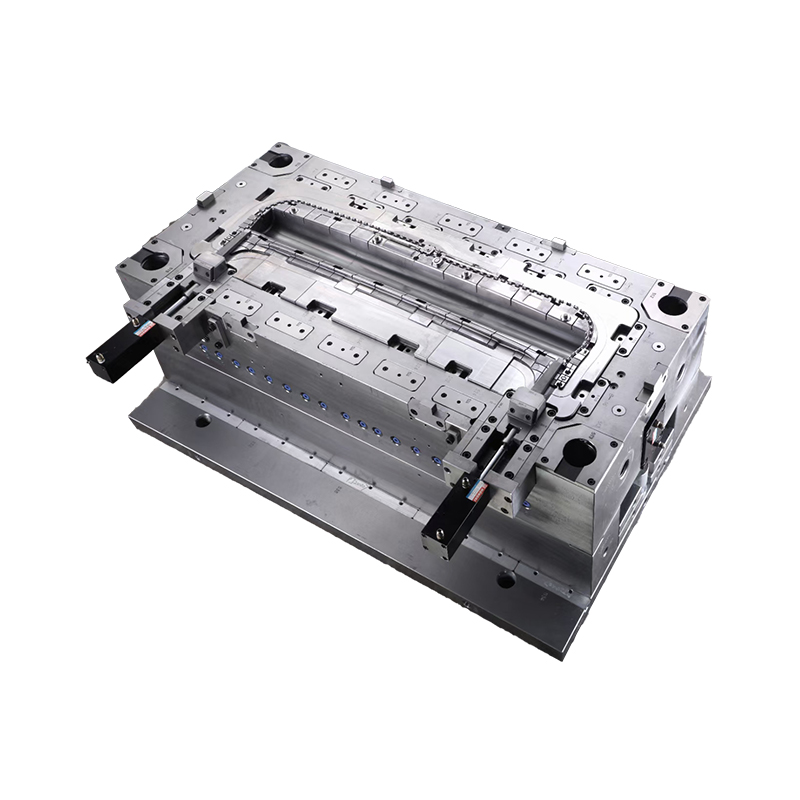

OEM Customized Plastic Injection Molding Processing – Customized plastic injection mold tooling of mechanical shell – DTG Detail:

Hot runners use a screw nozzle that is fed by a barrel using a pump, while cold runners use a closed, thermoset mold. The primary task of any injection runner system is to direct the material flow from the sprue to the mold cavities. The system requires additional pressure to push the material through the runner.

A hot runner makes it easier for a molding machine to inject plastic into a mould cavity. A hot runner increases the capability of a molding machine. It reduces the plastic flow length so a molder can save material by making thinner and lighter parts

The mold is designed with AB board structure and ejected by ejector pin. It can be automated production. The hot runner dispensing and feeding method can shorten the injection molding cycle and save the plastic material of the runner, thereby reducing costs, improving product quality and reducing waste. During the molding process of the hot runner mold, the temperature of the plastic melt is accurately controlled in the runner system. Elimination of follow-up procedures is conducive to production automation. Expand the application of injection molding technology.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

Product detail pictures:

Related Product Guide:

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for OEM Customized Plastic Injection Molding Processing – Customized plastic injection mold tooling of mechanical shell – DTG, The product will supply to all over the world, such as: Ecuador, Lahore, Atlanta, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

This supplier stick to the principle of Quality first, Honesty as base, it is absolutely to be trust.

Send your message to us:

-

2021 Good Quality Plastic Injection Box Molds -...

-

Best quality Precision Plastic Injection Mould ...

-

Cheap PriceList for Parts Injection Mould - Cu...

-

Top Quality Plastic Injection Mould Mould Desig...

-

OEM/ODM Factory Dies - Customized ABS Car Lamp...

-

OEM Customized Plastic Pump Spraying Mould - P...