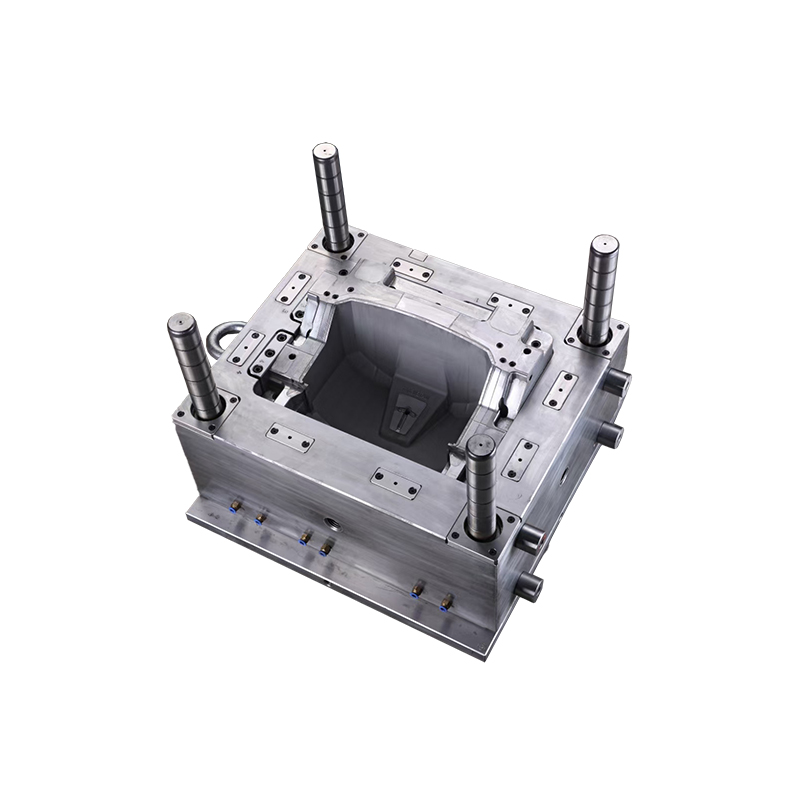

OEM manufacturer Auto Parts Moulds - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG Detail:

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.

Product detail pictures:

Related Product Guide:

Persisting in High top quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for OEM manufacturer Auto Parts Moulds - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG, The product will supply to all over the world, such as: Romania, Indonesia, Turkey, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.